Posts

405

Joined

6/6/2017

Location

VA

US

Edited Date/Time

6/29/2017 4:04pm

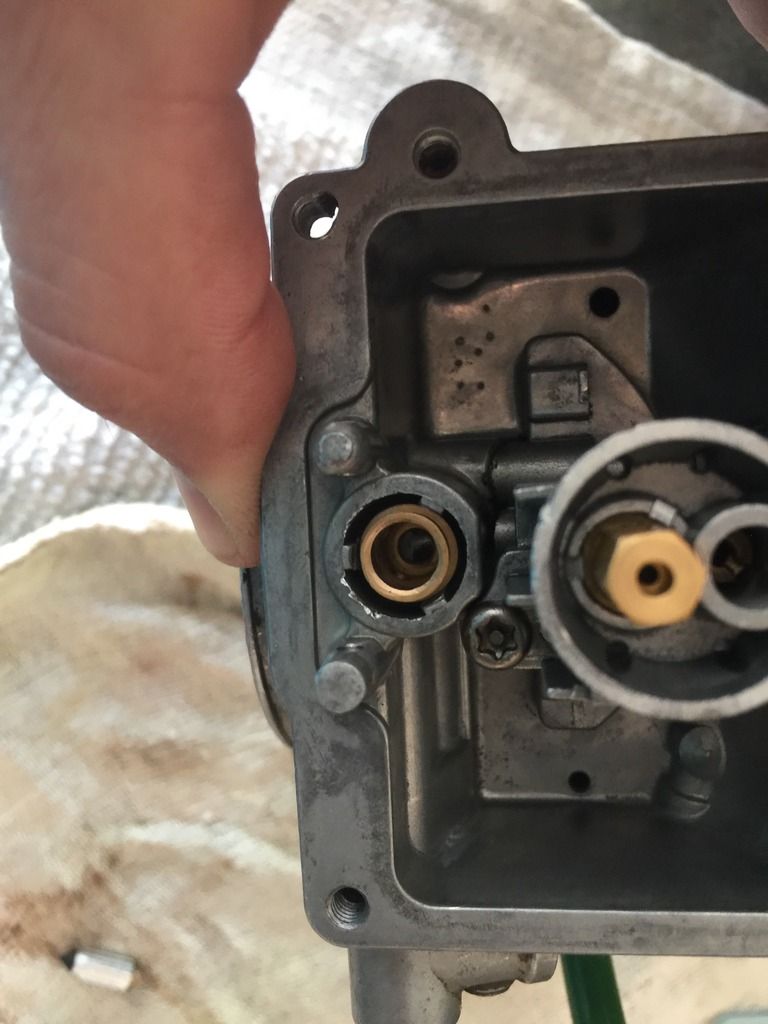

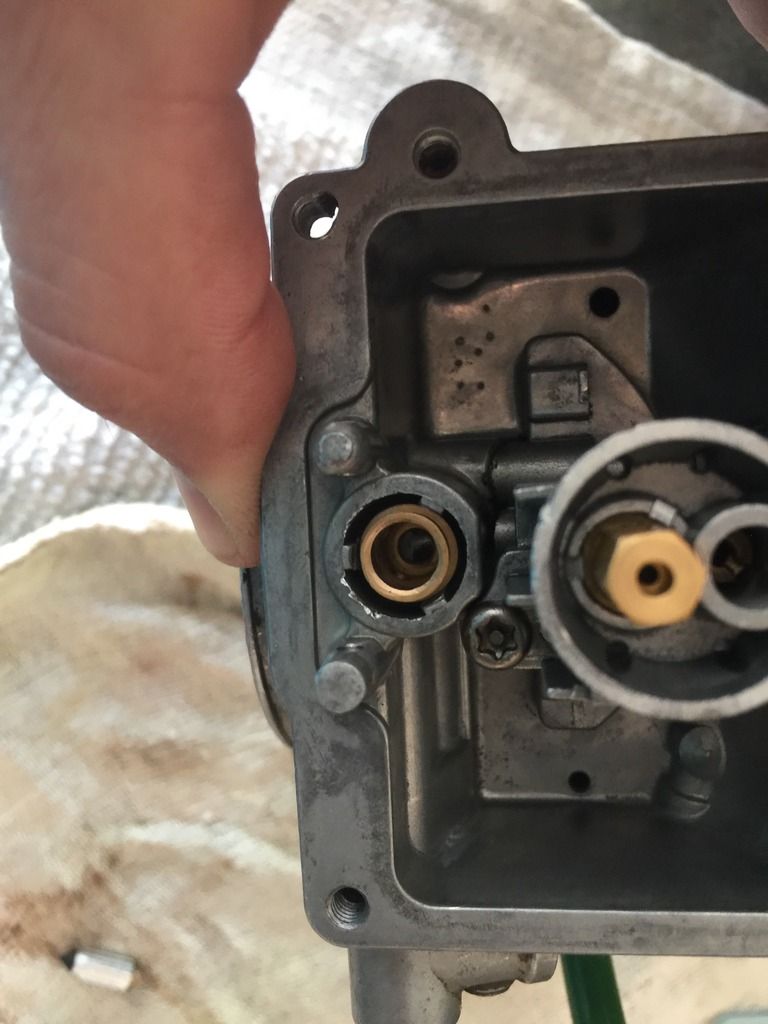

So as previously stated i bought a 2000 kx 125 used... the bike was leaking fuel and running rich as a sob . i finally got to tear into the carb and the jetting is set according to the manual , and it was still leaking... so i bought a rebiuld kit from fleabay " SMH" i have two different float valves and neither work ... the one that was in there was very tall and the new one i got will not sit inside the housing flush with the spring on it as it is to short ... the one that was in there measures 11mm from the top of the groove to the bottom where it sits ... the smaller one is 7mm i measured the hoising with a depth gauge and got 10mm ... am i missing something .. is this actually a pwk 36s? would it matter... really stumped here because i tested both with a fuel line and both leak as if them may not even be the right diameter .. anyone that can point me in the right direction thanks .

EDIT: If you can tell me if it is missing something or what .. the previous owner stated something about an oring which not sure where but there is no or ing located around the float valve on this carb.

EDIT: If you can tell me if it is missing something or what .. the previous owner stated something about an oring which not sure where but there is no or ing located around the float valve on this carb.

The length of the float needle valve that you need should measure about 14.25 mm from the rubber point to the top of the plunger(compressed)

I do NOT see any missing parts in the pic that you have posted. The rubber on the bottom of the float needle is what seals that hole.

How are you testing to see if the float needle is working correctly ? I don't understand with the fuel line. You are putting the bowl back on and letting it fill up ?

The Shop

1. take q tip and wrap super fine steel wool on the end, small enough to fit inside brass hole for fuel(aka needle seat).

2. put q tip in drill and other end inside carb brass hole, clean and shine up inside of brass hole and make sure there is no ob-longed, or egg shaped holes. Clean with contact cleaner and blow out.

3. lightly clean tip of float needle with white rag and contact cleaner, very light pressure, don't tear black rubber tip, look at black tip and make sure it's not jacked up at all, check the picture on line against your needle because you have 2 different size ones, not sure why, but one is way wrong in size.

3A. Make sure float has no hole in it, shake it for fuel inside, or put in water and see if floats, clean with contact cleaner and blow off.

4. put the float and needle together with carb, DO NOT put bowl on carb

5.keep carb upside down, put hose on brass fuel inlet and use mouth to suck and hold pressure with your tongue, do this several times and make sure it will hold pressure with your tongue after you suck down the needle. When releasing pressure it should go "pop" in your mouth...

6. next, leave bowl off, and hook IV system(your gas tank up high on shelf) fuel to carb with long fuel line, keep carb upside down, now turn on fuel from IV fuel system and it should NOT leak out of needle until you pull up on the float, and when you release the float it should stop flowing again, test this several times, this is the real way we test carbs before we mount them to insure it won't spill fuel everywhere after you've mounted it.

7. if it won't hold pressure with your tongue, or it leaks upside down with test fuel supplied, it will 100% leak on motorcycle. if both of these are good and it still leaks on bike check for super fine crack in brass tube coming up from float bowl, plug the bottom of the drain tube on float bowl and use mouth to blow into brass tube, it should not leak air when plugging the bottom. There is never a leaking carb gets past me, no way.

Just clean the seat with the q tip and steel wool, make sure the hole is not egg shaped.

If it leaks at the needle seat you should see some imperfection causing the leak.

Either the hole is dirty scored, or your needle has a bad tip?

You probably have a bad needle and the one in that kit you got is the wrong one, so you still need a new needle?

Post a reply to: Keihin PWK 36S issues